- / HOME

03

We see environmental protection as a key factor underpinning the sustainability of our business model. That applies both to our own activities and to those at our suppliers.

Our innovative technologies and products, which drive our success and whose technology performance capacity has convinced our customers worldwide, make a decisive contribution in this respect

AIXTRON’s products make it possible to save significant volumes of CO2 : Efficient semiconductor components based on gallium nitride and silicon carbide massively increase energy conversion efficiency and thus help to protect natural resources. We are also actively working to enhance the resource-efficient production and development of our equipment.

Dr. Felix Grawert · Chief Executive Officer (CEO)

Our customers benefit from groundbreaking solutions that also save costs, protect resources, and are energy efficient. These customers include companies operating in sectors such as e-mobility (powertrains, charging infrastructure), renewable energies (network switching), IT infrastructure (electricity supply), entertainment electronics (3D sensor technology, fast-charging devices), data transmission (fiber optic networks), and telecommunications (5G networks).

We are also making a substantial contribution to advances in the digital transformation of the display technology (Mini and Micro LEDs), lighting, and hygiene segments. AIXTRON equipment is used to produce devices for numerous innovative applications, technologies, and industries.

Examples include laser, LED, and display technologies, energy management and conversion, communications, signal and light technology, and numerous other sophisticated high-tech applications that facilitate pioneering, high-performing, and energy-efficient use and thus serve a whole series of megatrends.

As a technology leader, we have played a key role in the further development of power electronics and the production process for more than 30 years now.

Specialists estimate that power electronics based on gallium nitride and silicon carbide have the potential to save up to 35 % of current energy needs. These materials make more efficient use of energy and avoid losses resulting from conversion into waste heat. As the market leader in these fields, AIXTRON is making a substantial contribution to climate protection.

Prof. Dr. Michael Heuken

Vice President Advanced Technologies

Our technologies are the centerpiece of next-generation power electronics and can make an important contribution towards combating global climate change.

With its “Action Plan on Financing Sustainable Growth”, the EU Commission mainly aims to provide the economic and financial system in the EU with a more sustainable structure and to achieve climate neutrality by 2050, i.e. by then the volume of CO2 emissions avoided or removed should equal the volume emitted. The centerpiece of this Action Plan is the EU Taxonomy Regulation, a standardized system for classifying environmentally sustainable economic activities. This Regulation defines six environmental objectives:

Under the EU Taxonomy Regulation, economic activities are “environmentally sustainable” if they

The assessment as to whether an economic activity makes a substantial contribution to one of the objectives and does no significant harm to the five other objectives is based on technical screening criteria.

At present, these criteria are only available for the first two of the EU’s environmental objectives (Climate Change Mitigation and Climate Change Adaptation). In view of this, disclosures can only be made for these two objectives for fiscal year 2021.

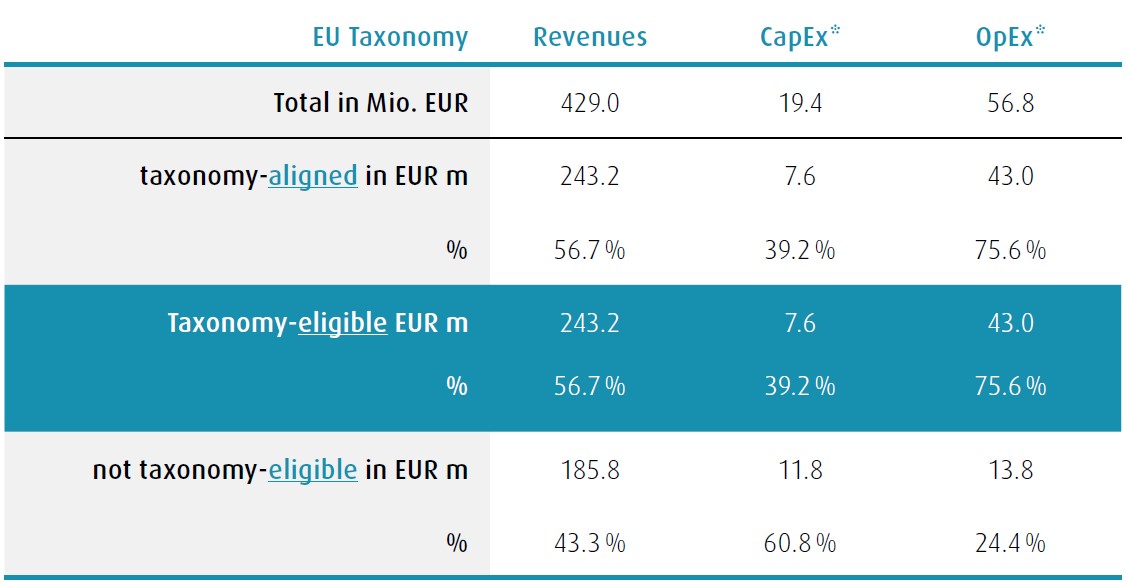

In view of the EU Taxonomy Regulation, in fiscal year 2021 we have reported for the first time on the taxonomy-eligible and, voluntarily, also on the taxonomy-aligned share of revenues, capital expenditure (CapEx)* and operating expenditure (OpEx)* for our economic activities.

In fiscal year 2021, a project was launched to implement the taxonomy requirements applicable to EU environmental objectives 1 Climate Change Mitigation and 2 Climate Change Adapation. The project team, which comprised experts from various departments, began by allocating our economic activities to the relevant taxonomy criteria. On this basis, interviews and workshops were then held with the respective contact partners and experts from the relevant specialist departments.

The purpose of these talks was to review whether the economic activites actually fulfill the relevant technical taxonomy criteria (alignment review). The assessments provided by the experts were documented and the relevant evidence and records inspected.

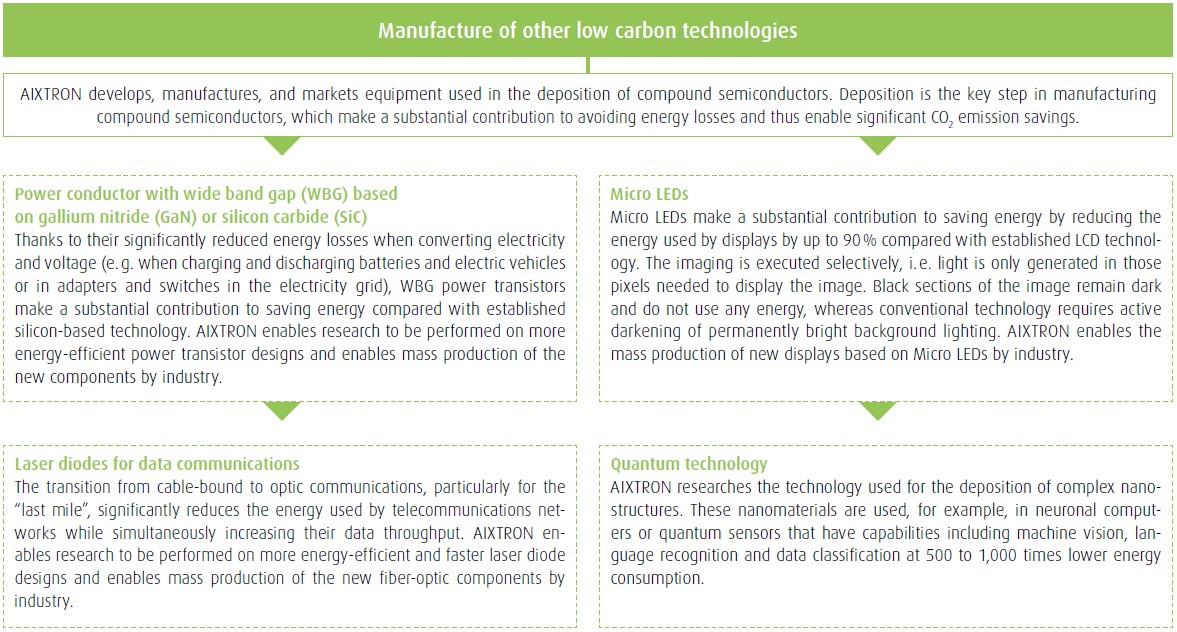

Large parts of our economic activities are not directly allocable under the taxonomy requirements. For the supplier industry, the set of criteria “Manufacture of other low carbon technologies” is particularly relevant. This set of criteria comprises economic activities in which technologies are manufactured that are aimed at and demonstrate substantial life-cycle GHG emission savings compared to the best-performing alternative technology available on the market.

To identify taxonomy-eligible economic activities, the project team identified those technologies in AIXTRON’s technology portfolio that can demonstrate low CO2 emissions in their application. In the next step, only those technologies leading to substantial GHG emission savings were classified as taxonomy-eligible and also as taxonomy-aligned. Against this backdrop, our taxonomy-eligible revenues are equivalent to our taxonomy-aligned revenues, as is also the case for CapEx* and OpEx*. The reduction in GHG emissions has to be substantial. However, the Regulation does not stipulate a minimum value.

It can be assumed that the purpose and objective of the “EU Action Plan on Financing Sustainable Growth” is to build on technological advances rather than on efficiency enhancements within the existing sytem. Emission savings of 20 % may regularly be deemed significant and thus make a substantial contribution towards protecting the climate. AIXTRON has taken this figure as its minimum threshold for substantial CO2 emission savings. A reference technology is the dominant technology on the market rather than a niche technologies with very small market share, however efficient such technologies may be. In respect of the reference standard, we have therefore referred solely to this reference technology.

The following approach was taken when analyzing taxonomy alignment:

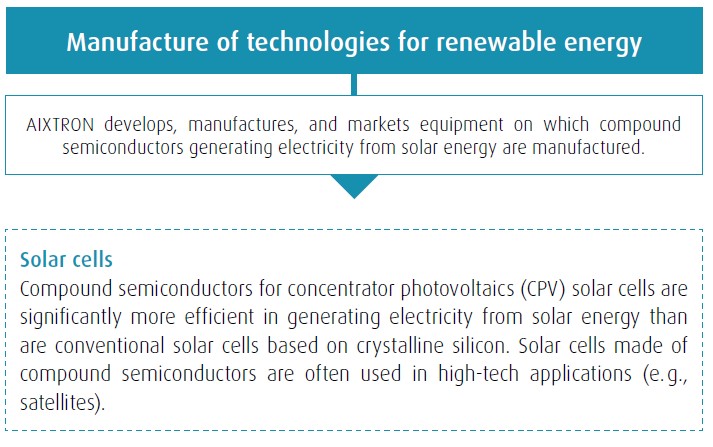

This analysis resulted in the identification of the following taxonomy-eligible and simultaneously taxonomy-aligned economic activities at AIXTRON which make a substantial contribution to the 1 Climate Change Mitigation environmental objective:

The analysis performed did not result in the identification of any economic activities making a substantial contribution to environmental objective 2 Climate Change Adapation.

The analysis performed did not result in the identification of any economic activities making a substantial contribution to environmental objective 2 Climate Change Adapation.

As a general rule, both the equipment used by customers and the equipment we ourselves use for research and development purposes is operated in a clean room environment. Clean rooms are equipped with extensive filtering systems to prevent any pollution of the surrounding environment.

In respect of the EU’s environmental objective 2 Climate Change Adaptation there are no indications that AIXTRON’s activities intensify the adverse impact of the current and expected future climate on AIXTRON itself or on people, the natural world or assets.

The criteria for the EU environmental objective for 3 water quality chiefly refer to legal and official requirements which AIXTRON is obliged to comply with. The same basically applies for the requirements of the EU Environmental Objective 5 Pollution Prevention and Control. There are no indications that AIXTRON has infringed any of the relevant requirements.

The Environmental Objective 4 Transition to a Circular Economy involves general requirements, such as long durability, easy maintenance and dismantling. The predominant share of our components are designed for very long lifetimes, are capable of being recycled, and still have monetary value at the end of their useful life (e. g. steel, stainless, aluminum, copper, electronics).

In respect of the EU’s environmental objective 6 Protection and Restoration of Biodiversity and Ecosystems AIXTRON performs environmental impact and comparable assessments within its own business activities in cases where there is a requirement to do so.

Information concerning compliance with the minimum standards in respect of occupational safety and human rights can be found in the chapter “Occupational health and safety” and the chapter “Conflict Minerals” of this report and in the “Sustainability” section of AIXTRON’s website.

Revenues as referred to in the EU Taxonomy Regulation are defined as net revenues pursuant to IFRS as stated in the consolidated income statement and only referring to fully consolidated subsidiaries. Further information about revenues can be found under “Development of Revenues” from Page 86 of the Annual Report.

CapEx as referred to in the EU Taxonomy Regulation is calculated on a gross basis, i. e. without accounting for remeasurements, depreciation and amortization, or impairment losses. CapEX comprises investments in non-current intangible assets and in property, plant and equipment as presented in the consolidated statement of financial position. Further information about CapEx can be found under “Investments” from Page 93 of the Annual Report.

Taxonomy-aligned and taxonomy-eligible shares of revenues, CapEx, and OpEx

Taxonomy-aligned and taxonomy-eligible shares of revenues, CapEx, and OpEx

OpEx as referred to in the EU Taxonomy Regulation includes expenses not eligible or capitalization that are presented in the consolidated income statement, such as expenses for research and development, building refurbishment measures, short-term leases, maintenance and repairs, and all other direct expenses resulting from the maintenance of property, plant and equipment in order to safeguard the operating capability of taxonomy-eligible assets. At AIXTRON, in the 2021 year under report this corresponded to research and development expenses (see “Operating Expenses” from Page 88 of the Annual Report).

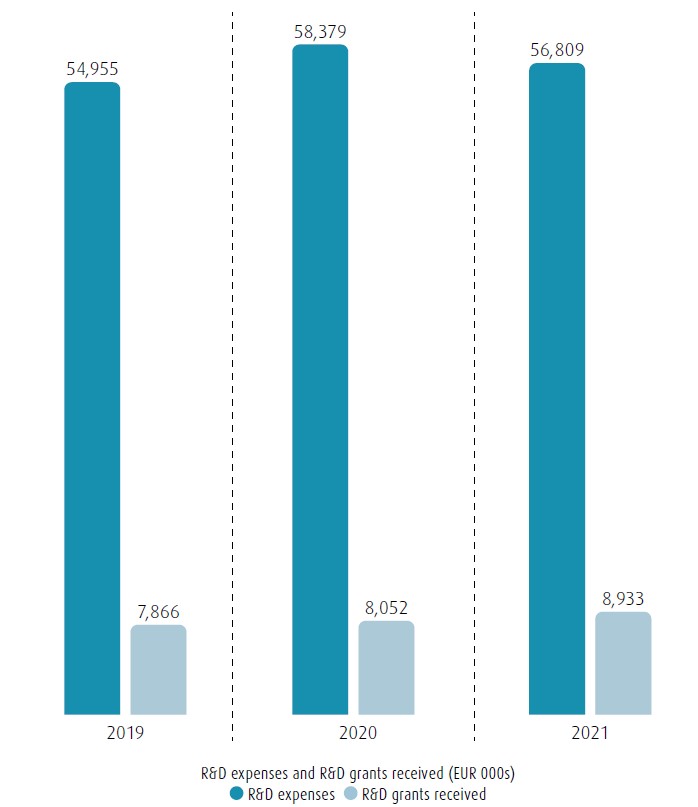

At our company, new technologies result from the targeted investments we make in our research and development. The R&D process begins in basic research with materials and then moves to processes and procedures. One decisive outcome of our research activities is our highly innovative product portfolio of technology solutions that have the potential to make the world faster, more sustainable, efficient and better. These enable us to offer better and more efficient products and solutions to our customers, while at the same time securing and extending our leading international position.

We cooperate with excellent universities, research centers, and industrial partners worldwide in order to implement sophisticated projects on national and international levels. These projects are developed on a basis of cooperation between equals. This way, we benefit from working with highly qualified partners while also being in demand ourselves as a partner for sophisticated projects.

In developing innovations for materials and processes, we work together very closely with our partners in joint projects that receive funding on national or European level. These close cooperations give rise to solutions that ultimately lead to marketable products.

The “Research and Development” section of AIXTRON’s 2021 Annual Report provides several examples of research projects in which AIXTRON is involved

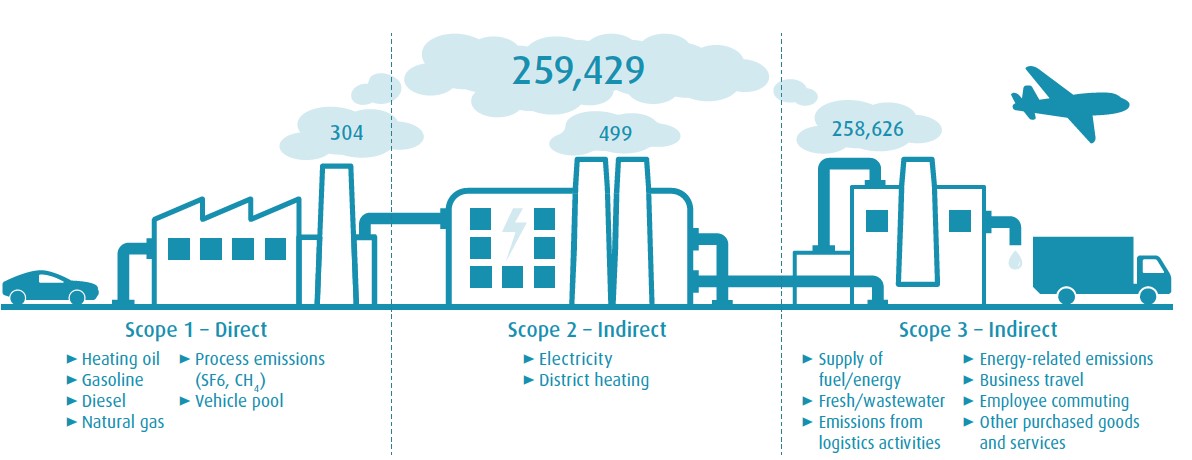

Having compiled a comprehensive climate balance sheet for the past year under report, we are for the first time able to report the total CO2 emissions incurred in connection with our business activities. In 2021, we emitted a total of 259,429 tonnes of CO2e*. Alongside the Scope 1 and 2 emissions already reported each year, this figure for the first time also includes all Scope 3 emissions relevant to our business activities. The Scope 3 emissions are not fully comparable with the 2020 figure as it is not possible to retrospectively calculate the emissions for logistics activities and waste. The main driver of the growth in Scope 3 emissions is the increase in other purchased goods and services, which rose from 119,364 tonnes of CO2e in 2020 to 227,738 tonnes of CO2e in 2021. This was due to the strong revenue growth in 2021 and additionally to the increase in inventories in preparation for further growth in 2022. A detailed overview of CO2e emissions per category can be found at the end of this report.

Overview of CO2 emissions (in tonnes of CO2e) for the 2021 year under report

Overview of CO2 emissions (in tonnes of CO2e) for the 2021 year under report

* To standardize the climate impact of different greenhouse gases, we refer to CO2 equivalents (CO2e) as the unit of measurement.

Since 2019, we have offset the unavoidable CO2 emissions resulting from our business activities (Scope 2 and part of Scope 3 emissions) by supporting two climate protection projects which bear the highest standard of certification. We selected the projects due to their positive impact on the environment, climate, and local populations. The emissions saved are regularly reviewed and confirmed by independent experts. In the interests of sustainable development, we decided last year to extend the period for which we are supporting the two projects by a further three years to 2023. Further details about the projects we support can be found on our website.

To provide a basis for our efforts to further reduce our own energy needs, we implemented an energy management standard meeting the requirements of ISO 50001:2011 at the German locations of AIXTRON SE many years ago already. Our successful conversion to the requirements of ISO 50001:2018 was confirmed in the recertification audit performed in 2020, which is valid until 2023.

At our German locations, we are continually working to improve our energy management systems. To this end, we are drawing on extensive evaluations that facilitate the targeted control and optimization of our systems and processes.

To enhance these evaluations, we continued with the cloud-based dashboard concept in the 2021 year under report, in which we installed new meters in order to optimize the control technology at the energy management center.

These electricity meters, which now number more than 160 in total, are read and evaluated at 15-minute intervals. As well as recording the data, the system offers an extensive calculation, evaluation, and documentation tool. Moreover, it enables targeted measures to be taken to reduce CO2 emissions and the success of these measures to be directly assessed. For this, we automatically generated a detailed report for the first time in the past year.

Since 2019, we have procured the electricity used at our European sites and in the USA exclusively from renewable energies. Furthermore, we installed a photovoltaics system at our Kaiserstrasse site many years ago already. All electricity generated by the system, which in 2021 amounted to 3,659 kWh (2020:3,476 kWh), is fed into the electricity grid.

Building on our systematic approach to energy management, we have already initiated and implemented numerous projects and measures to sustainably reduce our energy consumption. The three most important projects implemented in the past year are provided as examples below.

In cooperation with a nationwide company, we introduced monitoring in our energy management center in 2017 and began continually adjusting and optimizing our measurement and control technology. This project, which ran to the end of 2021, generated savings totaling around 42,000 kWh in its final year.

Here too, we cooperated with a nationwide company to continually adjust and optimize our measurement and control technology by working with permanent monitoring. The project generated savings of around 54,000 kWh in total last year.

In the past year under report we replaced the filters in our ventilation systems with more efficient versions and thus saved 60,000 kWh in total (calculated over one year).

* In calculating our energy and CO2 savings, we were assisted by external companies who provided us with technical advice based on their engineering skills and specialist expertise. All calculations have been based on a systematic and scientifically substantiated approach with specific assumptions for the individual calculations.

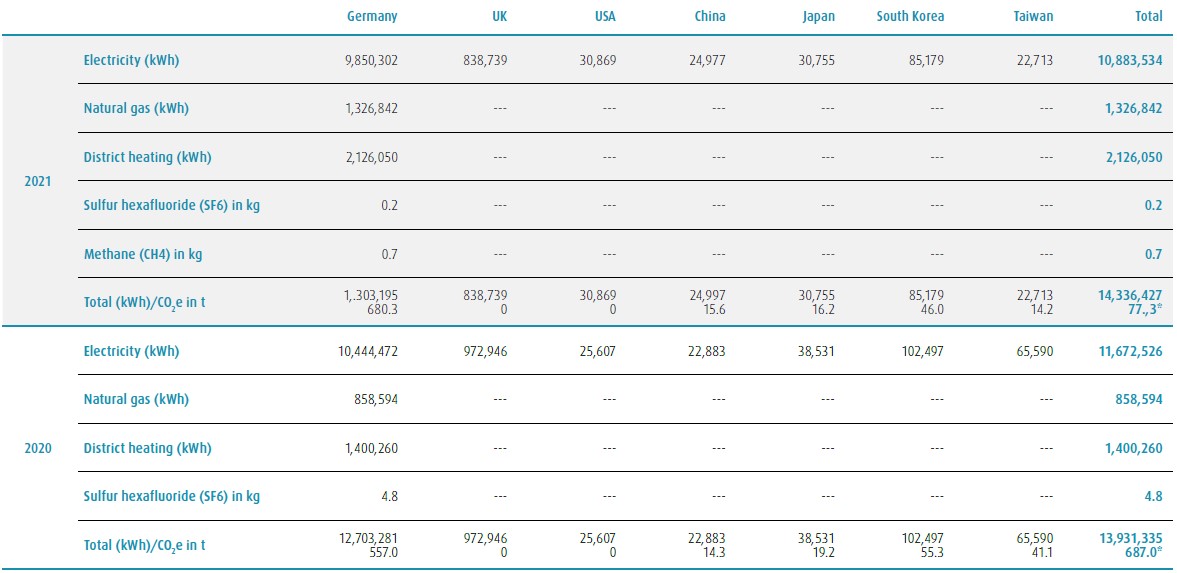

We significantly increased our revenues in the past fiscal year, a development which was accompanied by higher energy requirements. Thanks to our various energy saving projects, however, we were able to prevent our energy consumption from increasing to the same extent as our business volumes. Energy consumption showed a slight increase of 2.9 % in the past fiscal year.

Our success here confirms us in our course and motivates to go even further. Each year, we review our status quo and set ourselves ambitious new energy saving targets. It goes without saying that this is also an economic factor for us, as lower consumption also reduces our costs.

We are continually developing our energy efficiency enhancement measures further. Our targets refer above all to our R&D and production sites in Germany and the UK.

Despite the significant growth in business volumes, our electricity needs of 10,883,534 kWh in 2021 were significantly lower than in 2020 (11,672,526 kWh). The energy saving projects already referred to were the main driver of this positive development.

At 3,452,892 kWh in total, our consumption of natural gas and district heating rose significantly compared with 2020 (2,258,854 kWh). The main reason for this increase was that, due to coronavirus protection measures, the fresh-air share of overall ventilation systems had to be raised from 10 % to 50 %. Not only that:

Due to the high level of humidity in the past year (caused by frequent heavy rain), the heat registers used to dehumidify the air had to be operated far more often than usual.

Energy consumption and process emissions (per- and polyfluoride chemicals sulfur hexafluoride (SF6) and methane (CH4)) at the AIXTRON Group. The reduction in South Korea is due to the discontinuation of APEVA’s activities in the year under report. The sharp reduction in Taiwan is due to political measures in connection with the coronavirus pandemic: on two occasions, colleagues worked from home over longer periods.

* The figure stated includes heating, process emissions and electricity and district heating (Scopes 1+2) but does not include the vehicle pool.

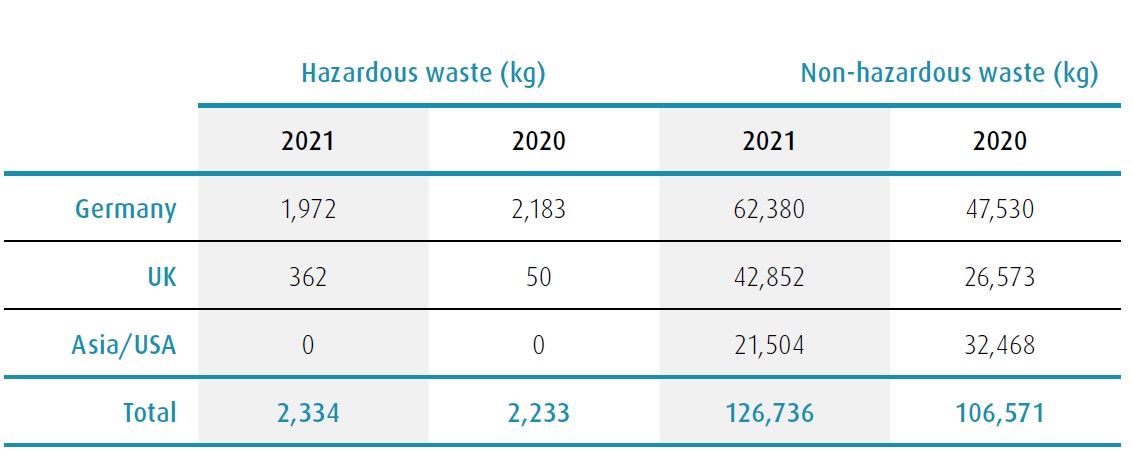

In producing its equipment, AIXTRON uses numerous materials whose purchase, transport, use, and disposal have an impact on people and the environment. This should be reduced to a minimum. Our top priority is to avoid waste arising in the first place, i.e. to minimize the materials consumed and resultant waste volumes. In our waste management, one factor that is therefore important to us – depending on the type of waste and recycling method involved – is to ensure separation and safe disposal of waste. The waste volumes incurred and then sent for recycling or disposal are recorded and classified on a local basis, with a distinction made between hazardous and non-hazardous waste. Wherever possible, residual materials are reused. Waste is reused in terms of its materials or incinerated. Where this is not possible, the waste is correctly disposed.

Hazardous substances and materials are used in the processing chambers of our equipment, and in some cases in the pipes as well. These substances and materials have to be disposed of separately. During disposal, the individual components and modules are collected in special containers that are secured in such a way that the hazardous materials cannot escape. At our European sites, we work with specialist local companies that dispose of the waste appropriately at regular intervals. The materials, some of which highly valuable (e.g. stainless steel), are recycled wherever possible and subsequently reused in the interests of a recycling-based economy. For exhaust gas cleaning, we rely wherever possible on catalytic cleaning processes which largely avoid the incurrence of hazardous waste. Our exhaust gas cleaning system avoids all wet-chemical processes, which means that no contaminated wastewater is incurred anywhere in our operations.

The slight increase in hazardous waste was due to a rise in the necessary number of test runs, as well as to the use of an improved and more precise calculation methodology at our location in Cambridge (UK).

The higher volume of non-hazardous waste in Herzogenrath (D) and Cambridge# (UK) was due to increased production volumes. This increase was partly offset by the reduction in waste volumes in the Asia and USA regions.

Hazardous and non-hazardous waste by region.

Hazardous and non-hazardous waste by region.

Given the complexity of our equipment, we have to provide our customers with targeted advice on location. Our presence is in some cases also required to develop analyzer systems together and to support customers in optimizing their use of the equipment or in training their staff. This generally requires our employees to travel. Our customers are mostly located outside Germany, a factor which influences the number of kilometers traveled and the means of transport selected.

We have a total of 15 electric car charging points and 24 e-bike battery chargers on our company premises. In the year 2021 year under report, further colleagues decided to use our battery charging infrastructure, as a result of which the number of participants (including the three Executive Board members) rose to 35 (2020: 16).

It is pleasing to note that many colleagues also come to work by bike and use the covered bicycle stands specially built for this purpose.

Given that we sell our equipment and technologies on a worldwide basis, it is not always possible to avoid air travel. We nevertheless always try to select other options wherever possible. For intercontinental journeys, however, flying is the only realistic option in day-to-day business.

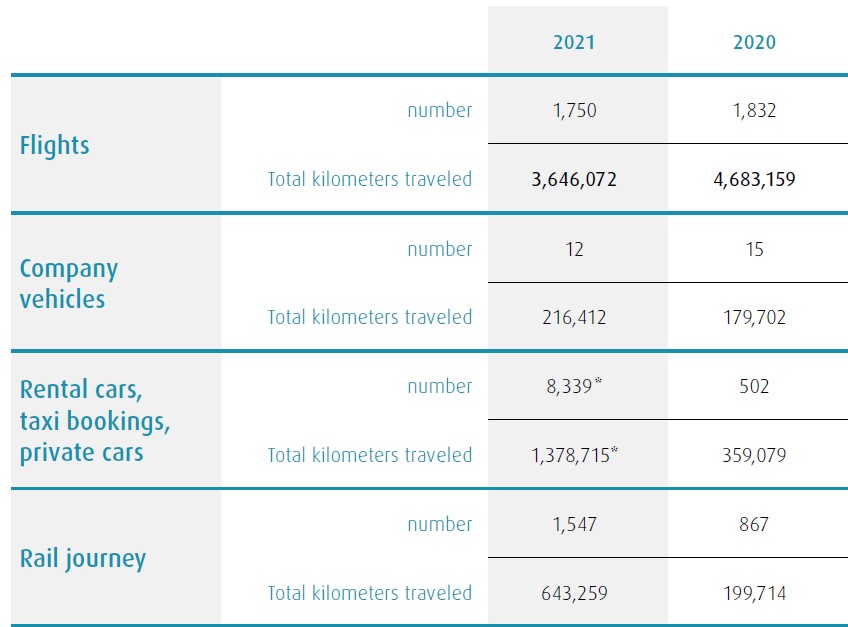

A total of 1,750 bookings were made in the 2021 year under report (2020: 1,832), with a total of 3,646,072 kilometers flown (2020: 4,683,159 km). This corresponds to a further year-on-year reduction of more than 22% (2020: 68 %) and corresponded to emissions of 1,237 tonnes of CO2e (2020: 1,589 tonnes of CO2e).

This further reduction was once again due to the political regulations and measures taken in connection with the coronavirus pandemic and the resultant restrictions on travel. Video conferences were substituted for many on-site meetings once again in the 2021 year under report.

In 2021, our company car pool comprised 12 cars (2020: 15), of which three powered by gasoline, three by diesel, five with hybrid drives and one purely electric vehicle. Consistent with our internal policy, since 2020 all new purchases of vehicles for the company pool have involved hybrid or electric cars. We are also endeavoring to expand the small to medium-sized vehicle classes in order to reduce the fuel consumed by the car pool thanks to the lower weight involved. A total of 216,412 km was traveled in 2021 (2020: 179,702 km), corresponding to an increase of 20 %.

In the 2021 year under report, our employees used rental cars, taxis, or their own private cars to drive a total of 1,378,715 km. As the journeys made by employees in their private cars and taxis have been included in the calculation for the first time in the year under report, the figure stated is not comparable with the previous year.

We encourage our staff to undertake as many business trips as possible by train. This is reflected in a threefold increase in the distance traveled by train. In 2020, our employees traveled a total of 199,714 km by train. In the 2021 year under report, this already surged to 643,259 km, corresponding to an increase of 18 %.

* Private car journeys made by employees and journeys by taxi have been included in the calculation for the first time. The figures stated are therefore not directly comparable with the previous year’s figure

Alan Tai

Taiwan/Singapore

Christof Sommerhalter

USA

Christian Geng

Europe

Hisatoshi Hagiwara

Japan

Nam Kyu Lee

South Korea

Wei (William) Song

China

AIXTRON SE (Headquarters)

AIXTRON 24/7 Technical Support Line

AIXTRON Europe

AIXTRON Ltd (UK)

AIXTRON K.K. (Japan)

AIXTRON Korea Co., Ltd.

AIXTRON Taiwan Co., Ltd. (Main Office)

AIXTRON Inc. (USA)

Christoph Pütz

Senior Manager ESG & Sustainability

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Ralf Penner

Senior IR Manager

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Prof. Dr. Michael Heuken

Vice President Advanced Technologies